Cable clamps and retainers are the elements that directly affect the stability of the entire cable system. They hold the conductors in the correct position, prevent them from shifting during short-circuit currents, and take on some of the mechanical and thermal loads. The IEC 61914 standard describes in detail what requirements such devices must meet and defines test procedures to verify their reliability under real electromechanical conditions.

Basic Requirements of IEC 61914

IEC 61914:2009, updated in 2015 and 2021, defines the criteria for cable clamps under various operating conditions. According to the standard, the device must provide:

- resistance to axial and lateral loads,

- resistance to dynamic and electromechanical forces in case of short circuit,

- heat resistance in a given temperature range,

- UV resistance, corrosion and flame propagation,

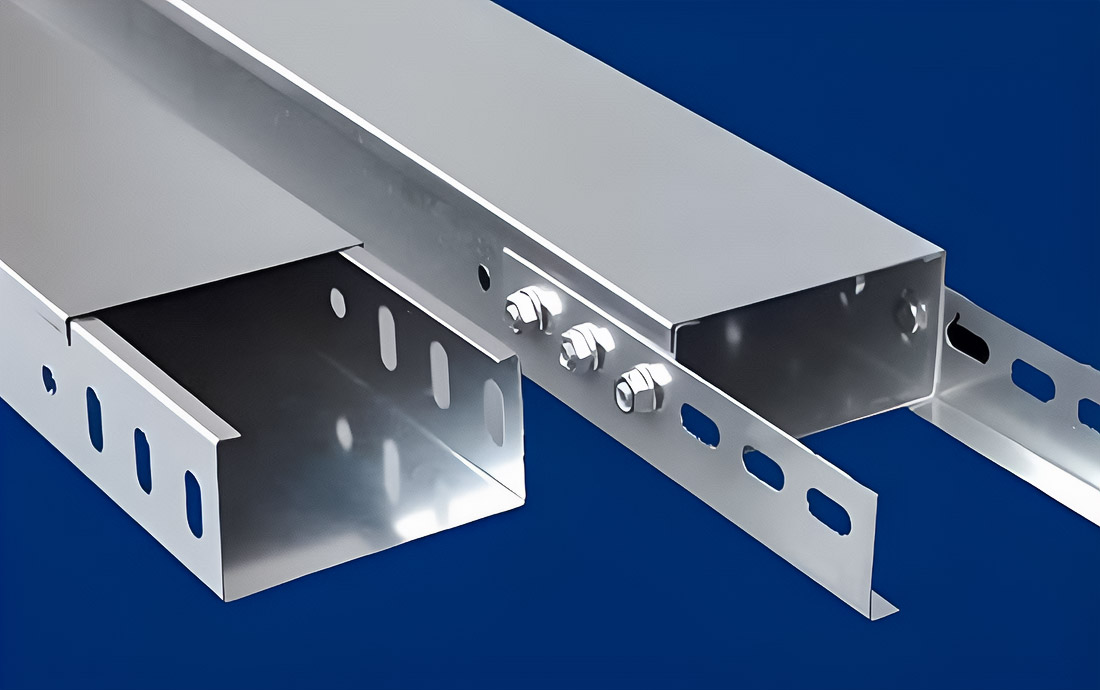

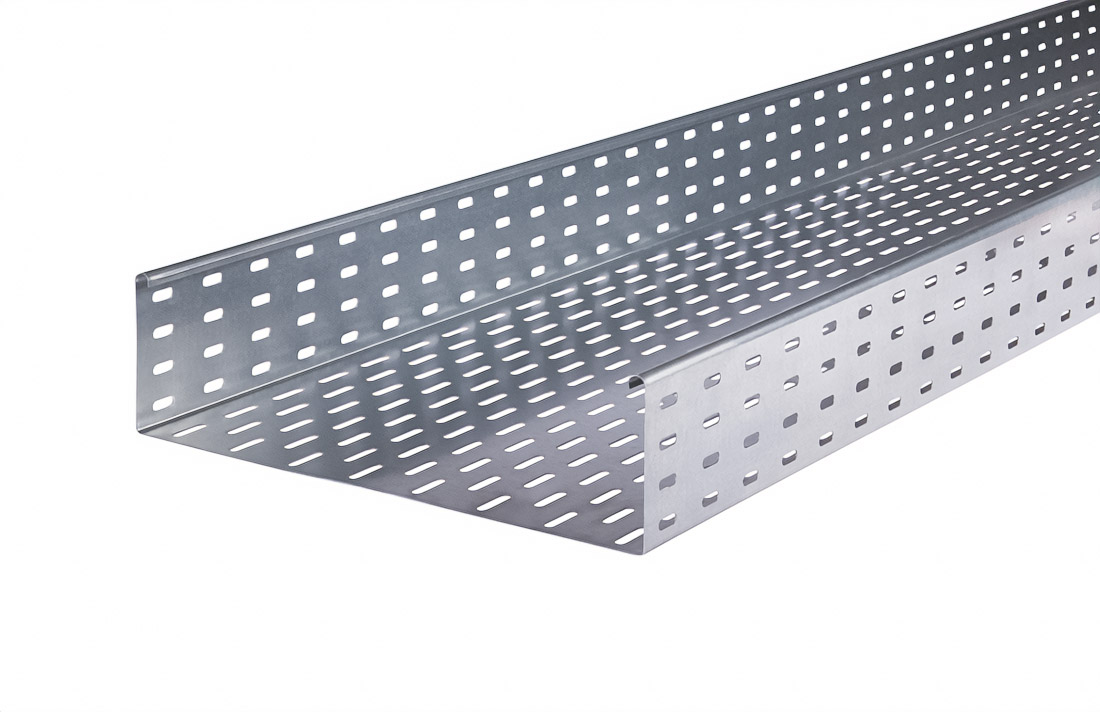

- reliable fixing of cables on mounting surfaces (trays, ladders, beams).

Special attention is paid to testing: the standard requires checking the terminals during a short circuit lasting 0.1 seconds, which corresponds to five full current cycles. It is during this time that the real strength of the cable clamp is manifested in conditions of a sharp electromechanical impact.

Short Circuit and load Calculation

A short circuit causes significant electromechanical forces between the conductors. To calculate them, IEC 61914 uses a formula that takes into account the peak current value (Ip2), the distance between the cable centers (S) and the length of the fixing section. In practical calculations, RMS conversion coefficients to peak current are used:

- at 10–20 kA – multiplier 2,

- at 21–50 kA – 2.1,

- at 51 kA and above – 2.2.

So, in the example with a peak current of 110 kA, for a triangular cable configuration with a diameter of 38 mm, it was optimal to install clips every 600 mm when using products with a loop strength of 36,000 N, or every 900 mm with a strength of 63,000 N. In another case, with an RMS current of 30 kA and a diameter of 33 mm, the calculation showed the need to use clamps with a strength of 15,000 N installed through 600 mm.

Mounting and Mounting Intervals

The correct distribution of cable clamps directly affects the stability of the entire system. Standard cable ladders have a pitch of 300 mm, which is convenient when designing. Recommended:

- the maximum distance in straight sections is 1500 mm,

- on bends and vertical tracks no more than 300 mm.

The choice of clips depends on the configuration of the cables: single, triangular or quadrofoil. Each of the schemes places different requirements on the holding capacity of the clamps.

Materials and Operating Conditions

The design takes into account mechanical stresses, temperature range and the environment. Polymer or aluminum clamps are sufficient for areas with low corrosion activity (C1–C2 according to ISO 9223). In conditions of medium aggressiveness (C3), 304 stainless steel and powder coating are used, and in marine and chemically active environments (C4) 316 stainless steel or marine aluminum is used. These solutions provide durability and resistance to aggressive factors. In many modern projects, clamps are mounted together with cable tray accessories, which simplifies integration into complex electrical networks.

Safety and Reliability

The use of cable clamps conforming to IEC 61914 reduces the risk of accidents in case of short circuits. Incorrectly selected clamps can lead to uncontrolled cable movement, fire, or equipment damage. Such scenarios are especially dangerous in data centers, industrial facilities, and energy systems, where even a short-term failure entails multimillion-dollar losses and a threat to personnel safety.

Cable clamps certified according to IEC 61914 are a mandatory element of modern electrical installations. They provide cable fixation, resistance to electromechanical forces, and durability when exposed to high temperatures, corrosion, and ultraviolet radiation. The correct calculation of the mounting intervals (300–1500 mm), consideration of short-circuit currents (from 30 kA to 110 kA and above) and a competent choice of materials for specific corrosion zones C1–C4 guarantee the reliability and safety of the systems. It is these factors that make cable clamps not an auxiliary, but a critically important part of the electrical infrastructure.

Surfer, hustler, hiphop head, reclaimed wood collector and recent OCAD grad. Acting at the intersection of design and programing to give life to your brand. Check me out on Dribbble or Medium.