Fabrics do not only help ease the way a shell structure is produced, but they also enhance the quality of clothes. Some components of fabrics that affect clothes quality include vitality, shrimps, pressure, trim and slope rigidity, thickness, cover characteristics and practical textures. You will learn more about the mistakes they cause as you continue reading, described in detail by our fabric building structures experts.

Color Variation

This is an easily noticeable defect in clothes. It means the variation in the color and shade from one piece to the other of the fabric. A professional company will help patch things up so the color and shade are the same throughout.

Stains

This is common with dyed fabrics. They are called spots of a color that is not the same as that of the fabric. The professional company will be of great help by making sure they clean their machines and tools used to remove oils, dyes and grease.

Smooth Lines

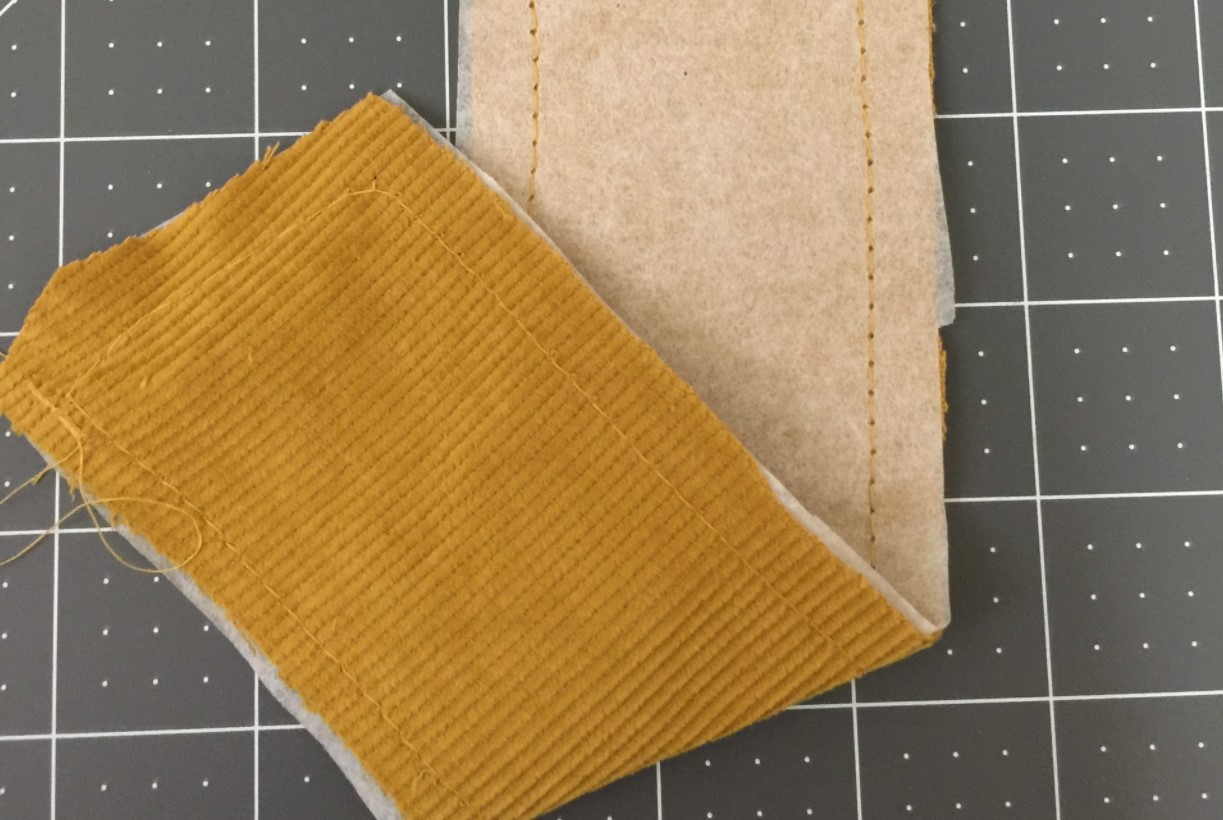

These are jagged lines that can be found on different parts of the fabric which can be as a result of aged thread tension and little mistakes in the bobbin. The professional company should ensure they check the tension and also the position of the thread regularly and make sure faults should be replaced immediately.

Stitches Droppings

Another common issue found with fabrics is stitch droppings. They are present in the fabrics known as mixed stitches and holes. The yarn feed rate needs to be regulated in the professional company frequently to avoid this.

Wrinkle Lines

This differs from crease stripes and appears once in the entire fabric. Truthfully, wrinkle lines can’t be avoided but can be minimized with proper maintenance.

Coloring Marks

These are uneven marks on the fabric that are often as a result of entanglement of dyeing machines, low quality of fabric base and incorrect PH that occur during the production process. Valid PH maintenance should be maintained during production and the fabric base should be checked regularly for any issue.

Printing of Fabric Issues

This is when the printing of the fabric came out wrong and it isn’t what users want. Uniform coloring, good scouring and levelling processes will help prevent this in the professional company.

Barre

Barre means a redundant visual structure of bars and stripes in the fabric that are made unknowing. This barre does remain unnoticeable until the fabric production is completed. They occur as a result of color, dye and physical mixtures in yarns of the fabric store duration.

In Conclusion

Good machine maintenance, consistent raw material labelling and organizations will help prevent this. A FIFO inventory system can also assist to ensure good material flow and usage during production. Sprung Structures can help you with it.

Surfer, hustler, hiphop head, reclaimed wood collector and recent OCAD grad. Acting at the intersection of design and programing to give life to your brand. Check me out on Dribbble or Medium.